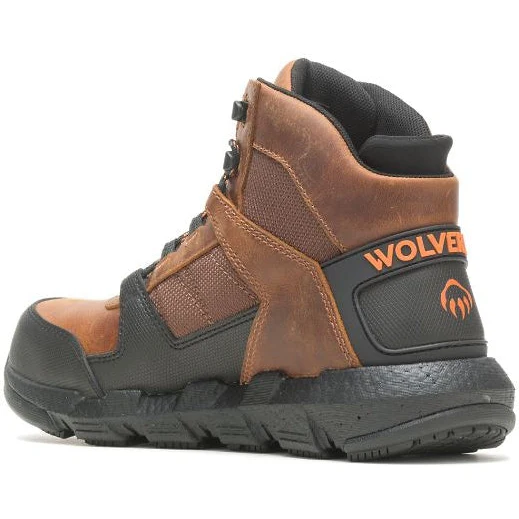

In the modern industrial landscape, the physical demands placed on the workforce have necessitated a shift in protective equipment design. For professionals standing on concrete or traversing uneven job sites for ten to twelve hours a day, the primary cause of fatigue is often the “energy drain” caused by repetitive impact. To combat this, leading engineers have moved beyond simple cushioning toward active energy return systems. Among the most innovative solutions in this category is the bates boots series, which has redefined the “sneaker-boot” hybrid by integrating high-rebound materials with industrial-grade safety standards. By utilizing a multi-layered approach to shock absorption, these boots allow workers to maintain a high level of performance while significantly reducing the long-term strain on their joints and lower back.

The Science of UltraSpring™: High-Rebound Performance

The core of the Rev series’ success is the proprietary UltraSpring™ midsole. Unlike traditional EVA foam, which can compress and “pack out” over time, UltraSpring is a high-rebound ETPU (Expanded Thermoplastic Polyurethane) material. This substance is composed of thousands of individual energy capsules that act like tiny springs. When the foot strikes the ground, the midsole compresses to absorb the kinetic energy, and as the foot lifts, that energy is released back into the gait. This “supercharged” ride is not just about comfort; it is a physiological tool that reduces the amount of metabolic energy required for each step. For a worker who walks several miles across a warehouse or construction site daily, this cumulative energy saving is the difference between an evening of recovery and an evening of chronic fatigue.

DuraShocks® Flex: Targeted Impact Management

Complementing the high-rebound midsole is the legendary DuraShocks® Flex technology. This system utilizes strategic compression pads located in the heel and the ball of the foot—the two primary impact zones of the human stride. These pads are engineered to dissipate the initial shock of a footfall before it travels up the skeletal system. In the Rev series, this technology has been updated with “Flex” channels in the outsole, which allow the boot to bend more naturally with the foot’s anatomy. This flexibility is vital for workers who frequently kneel, squat, or climb ladders, as it prevents the stiff, board-like feeling that often leads to foot cramps and localized pressure points.

CarbonMAX®: The New Standard in Safety Toe Technology

Safety remains the non-negotiable foundation of any work boot. However, the weight of traditional steel toes has long been a source of complaints regarding foot fatigue. The Rev series utilizes CarbonMAX® nanotechnology to provide a safety toe that is significantly lighter than steel while maintaining the same ASTM F2413-18 M/I/C EH ratings. By using millions of carbon nanotubes arranged in a honeycomb pattern, Wolverine has created a toe cap that is thinner and lighter but incredibly strong. Because carbon fiber is non-conductive, these boots do not transfer heat or cold, keeping the toes at a more regulated temperature in extreme weather conditions. Furthermore, the thinner profile of the CarbonMAX toe allows for a more streamlined, “low-profile” look that transitions easily from the job site to casual environments.

Breathability and the “Vent” System

Temperature regulation is a critical component of all-day wearability. The Rev series often features specialized “vent” sides—perforated panels within the premium full-grain leather upper that facilitate airflow. This is paired with a moisture-wicking mesh lining that pulls perspiration away from the skin. In a closed-loop system, sweat can lead to friction, which in turn causes blisters and fungal issues. By creating a breathable microclimate within the boot, Wolverine ensures that the foot stays dry and comfortable even during high-exertion tasks in humid environments. The inclusion of a removable dual-density PU footbed further enhances this comfort, providing a soft initial step-in feel that can be customized with orthotics if necessary.

Reliability in Traction: The Rubber Lug Outsole

A boot is only as good as its connection to the ground. The Rev series is finished with a high-traction rubber lug outsole that is specifically engineered to be oil- and slip-resistant. The lug pattern is designed to “channel” fluids away from the contact points, ensuring a firm grip on slick, hydraulic-oil-covered concrete or wet metal surfaces. This stability is reinforced by a nylon shank, which provides the necessary arch support and torsional rigidity to prevent the foot from twisting on uneven terrain. This combination of “sneaker-like” agility and “tank-like” stability makes the Rev series a versatile tool for various trades, from warehouse logistics to residential construction.

Ultimately, the choice of footwear is a strategic decision that affects a professional’s health and career longevity. As the industry moves toward more ergonomic and responsive designs, the integration of athletic technologies into the workspace is becoming the standard. Achieving peak performance on the job requires gear that works as hard as the person wearing it. Finding these high-tech solutions through a dedicated provider like Boots Plus More ensures that you have access to the most advanced protective gear available today. By investing in the science of comfort and the integrity of modern materials, you empower yourself to face the challenges of the workday with confidence, resilience, and unyielding energy.